Add to Cart

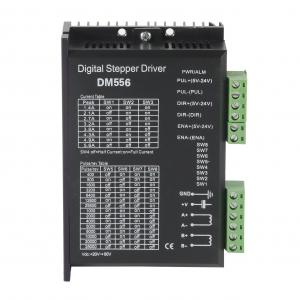

20-50VDC Stepper Motor Driver 5.6A Nema 23/24 stepping motor

DM556 Supply voltage range from 20VDC to 50VDC, suitable for driving various 2-phase hybrid stepping motors which phase current below 5.6A. The micro-step can be set from full step to 25600steps/rev and the output current can be set from 2.1A to 5.6A; with automatic idle-current reduction, self-test, over-voltage, under-voltage and over-current protection.

The DM556 is a new generation digital 2-phase stepper motor driver, based on a 32-bit DSP processor, combination of the anti-resonance, low noise, micro-step and low temperature rise technology significantly improve the performance of the stepper motor, has low noise, small vibration, low temperature rise and high-speed torque. The driver use online adaptive PID technology, without manual adjustment can be automatically generated optimal parameters for different motors, and achieve the best performance.

Features:

Electrical Specifications:

| Parameter | Min | Typical | Max | Unit |

| Input Voltage(DC) | 20 | - | 50 | VDC |

| Output current | 0 | - | 5.6 | A |

| Pulse Signal Frequency | 0 | - | 200 | KHZ |

| Input Signal Current | 7 | 10 | 16 | mA |

Current setting:

| Peak | SW1 | SW2 | SW3 |

| 1.4A | on | on | on |

| 2.1A | off | on | on |

| 2.7A | on | off | on |

| 3.2A | off | off | on |

| 3.8A | on | on | off |

| 4.3A | off | on | off |

| 4.9A | on | off | off |

| 5.6A | off | off | off |

Standstill Current Setting:

SW4 is used for standstill current setting. OFF means that the standstill current is half of the dynamic current; and ON means that standstill current is the same as the selected dynamic current. Usually the SW4 is set to OFF, in order to reduce the heat of the motor and driver.

Micro-step Setting:

| Step/Rev | SW5 | SW6 | SW7 | SW8 |

| 400 | off | on | on | on |

| 800 | on | off | on | on |

| 1600 | off | off | on | on |

| 3200 | on | on | off | on |

| 6400 | off | on | off | on |

| 12800 | on | off | off | on |

| 25600 | off | off | off | on |

| 1000 | on | on | on | off |

| 2000 | off | on | on | off |

| 4000 | on | off | on | off |

| 5000 | off | off | on | off |

| 8000 | on | on | off | off |

| 10000 | off | on | off | off |

| 20000 | on | off | off | off |

| 40000 | off | off | off | off |

Control signal Connector

| Control Signal connector | |

| Name | Description |

| PUL+ | Pulse signal positive |

| PUL- | Pulse signal negative |

| DIR+ | Direction signal positive |

| DIR- | Direction signal negative |

| ENA+ | Enable signal positive, usually left unconnected(enable) |

| ENA- | Enable signal negative, usually left unconnected(enable) |

Problems and Solutions:

Applications:

Suitable for a variety of large-scale automation equipments and instruments. For example: labeling machine, cutting machine, packaging machine, plotter, engraving machine, CNC machine tools and so on. It always performs well when applied for equipment which requires for low-vibration, low-noise, high-precision and high-velocity.